Water pressure switches maintain optimal performance in residential, commercial, and industrial water systems. However, like any mechanical or electrical component, they can develop issues over time. Recognizing common problems—and knowing how to troubleshoot them—can save time, money, and prevent system failures. In this article, we’ll explore the most frequent issues affecting water pressure switches, their causes, and step-by-step solutions.

1. Pressure Switch Fails to Activate the Pump

Symptoms:

- The pump does not start, even when water pressure is low.

- No audible “click” from the switch when pressure drops.

Possible Causes:

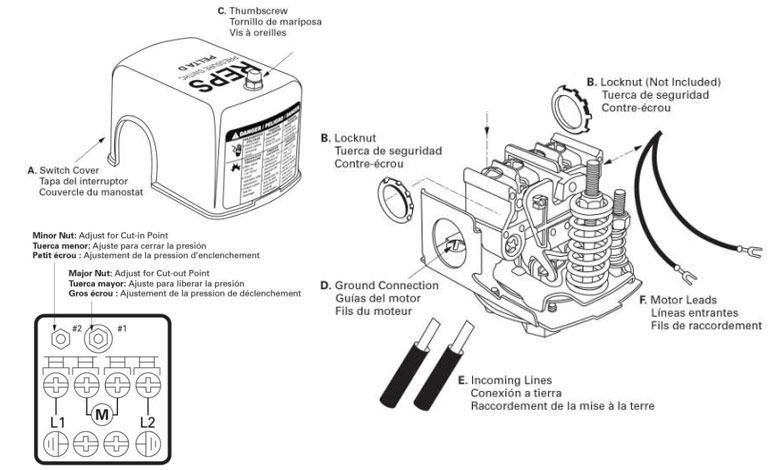

- Electrical Failure – Loose wiring, blown fuse, or tripped breaker.

- Clogged Pressure Port – Debris or sediment blocking the switch’s sensing mechanism.

- Burnt Contacts – Worn-out electrical contacts preventing current flow.

- Incorrect Pressure Settings – Cut-in pressure set too high.

How to Fix It:

- Check Power Supply – Verify that the circuit breaker is on and voltage reaches the switch.

- Inspect Wiring – Tighten loose connections and replace damaged wires.

- Clean the Pressure Port – Use compressed air or a small wire to clear blockages.

- Test the Contacts – If burnt, replace the pressure switch.

- Adjust Settings – Lower the cut-in pressure if necessary (consult the pump manual).

2. Pump Short Cycling (Rapid On/Off Switching)

Symptoms:

- The pump turns on and off too frequently.

- Water pressure fluctuates rapidly.

Possible Causes:

- Waterlogged Pressure Tank – Loss of air charge in the bladder tank.

- Leaking Pipes or Valves – Pressure drops due to water loss.

- Faulty Pressure Switch – Sticking contacts or incorrect calibration.

How to Fix It:

- Check the Pressure Tank – Drain the tank and measure air pressure with a gauge. Recharge to 2 psi below the cut-in pressure.

- Inspect for Leaks – Repair any leaks in pipes, fittings, or valves.

- Replace the Switch – If contacts are stuck, install a new pressure switch.

3. Pump Runs Continuously Without Shutting Off

Symptoms:

- The pump runs nonstop, even when pressure is high.

- Excessive noise or overheating.

Possible Causes:

- Stuck Pressure Switch – Contacts welded together due to arcing.

- Faulty Check Valve – Water flows backward, preventing pressure buildup.

- Incorrect Pressure Settings – Cut-out pressure set too high.

How to Fix It:

- Test the Switch – Manually tap the switch to see if it disengages. If not, replace it.

- Inspect the Check Valve – Replace if faulty to prevent backflow.

- Adjust Pressure Settings – Lower the cut-out pressure to the pump’s rated limit.

4. Inconsistent or Low Water Pressure

Symptoms:

- Weak water flow despite the pump running.

- Pressure gauge shows unstable readings.

Possible Causes:

- Clogged Switch or Pipes – Sediment buildup restricts water flow.

- Failing Pump – Worn impeller or motor issues.

- Undersized Pressure Tank – Cannot maintain steady pressure.

How to Fix It:

- Flush the System – Remove debris from pipes and the pressure switch.

- Test Pump Performance – Check amp draw and output pressure; repair or replace if needed.

- Upgrade the Pressure Tank – Install a larger tank for better pressure stability.

5. Electrical Problems (Tripped Breakers, No Power)

Symptoms:

- Pump won’t start, and the breaker trips repeatedly.

- Burning smell or scorch marks near the switch.

Possible Causes:

- Overloaded Circuit – Pump draws too much current.

- Short Circuit – Damaged wires or moisture in electrical components.

- Wrong Voltage Rating – Mismatched switch and pump voltage.

How to Fix It:

- Reset the Breaker – If it trips again, disconnect the pump and inspect wiring.

- Check for Shorts – Replace frayed wires and dry any wet components.

- Verify Voltage Compatibility – Ensure the switch matches the pump’s requirements (e.g., 120V vs. 240V).

6. Pressure Switch Leaking Water

Symptoms:

- Water dripping from the switch housing.

- Corrosion or rust on electrical contacts.

Possible Causes:

- Cracked Diaphragm – Wear and tear over time.

- Loose Fittings – Poor seal at pipe connections.

How to Fix It:

- Replace the Diaphragm – Install a new switch if the internal seal is broken.

- Tighten or Re-seal Fittings – Use thread sealant or Teflon tape on pipe threads.

Preventive Maintenance Tips

To avoid frequent pressure switch failures:

✔ Monitor Pressure Regularly – Use a gauge to check for abnormal fluctuations.

✔ Clean the System Annually – Flush tanks and pipes to prevent sediment buildup.

✔ Inspect Electrical Components – Look for corrosion or loose connections.

✔ Replace Old Switches Proactively – Typical lifespan is 5–10 years.

Conclusion

Water pressure switch issues can disrupt your entire water system, but most problems are fixable with basic troubleshooting. By understanding symptoms like short cycling, continuous operation, or electrical faults, you can take quick action to restore functionality. For complex issues, consult a professional to avoid further damage.

Reps Global Group LLC. Content Team

Keywords: water pressure switches, issues, troubleshooting, system failures, pump, symptoms, electrical failure, loose wiring, blown fuse, tripped breaker, clogged pressure port, debris, sediment, sensing mechanism, burnt contacts, current flow, incorrect pressure settings, cut-in pressure, power supply, voltage, inspect wiring, replace damaged wires, clean pressure port, compressed air, test contacts, short cycling, rapid on/off switching, fluctuating pressure, waterlogged pressure tank, air charge, bladder tank, failing pump, impeller, motor issues, undersized pressure tank, flush system, test pump, upgrade pressure tank, electrical problems, tripped breakers, no power, overloaded circuit, short circuit, damaged wires, wrong voltage rating, leaking water, cracked diaphragm, loose fittings, replace diaphragm, re-seal fittings, thread sealant, Teflon tape, preventive maintenance, monitor pressure, clean system, inspect components, replace old switches